AC / DC Motors, Generators & Pumps

Variable Frequency Drives

Engine Shut Down Systems

Switchgear

Breakers

SCR Systems

Motor Starters & Controls

Sync Systems

Generator Panels

Automatic Transfer Switches

Whether it's an install for a new-build, a removal for maintenance, or commissioning of a new motor, generator or pump, our decades of experience will ensure consistent productivity.

We will evaluate the condition of the mounting skid, the coupling, the electrical system and anything related to the system that could compromise the performanve of the packaged unit and recommend a plan of repair.

Your electric motor, generator, or pump will then be repaired to better than new condition using exacting standards like EASA, NEMA, IEEE, ISO, IEC, ANSI-ASMEB73.1, API 610, DIN 24256, and UL-NFPA20.Units will be run tested with vibration measurements captured in a controlled environment.

Alignment is a critical part of any successful preventative maintenance program, as misalignment is responsible for a large portion of damage to rotating electrical equipment.

Tight machine tolerances and precision bearings require proper alignment to minimize vibration and premature failure. Excessive vibration from misalignment is carried through to components such as bearings and couplings that reduce their lifespan and reliability.

Coupling failure, bearing failure and catastrophic machine failure due to rotating components contacting non-rotating components can be minimized through proper alignment.

Our laser alignment tools produce reports that can be compared to readings obtained at scheduled maintenance intervals to identify excessive movement in coupled machines.

Vibration analysis is the science of monitoring vibration patterns of motors, pumps and generators, and then predicting their maintenance needs.

Our factory-trained and certified vibration analysts can help pinpoint the cause of premature failures through trending vibration patterns. We can then correct the problem, whether it is a worn bearing fit, a needed laser alignment, a field or shop balance of the rotating assembly. Our field balance units work on any motor or generator that has exposed end rings on the rotor and our in-house balancer can balance rotating assemblies up to weights of 25,000 pounds.

Unbalanced rotating machinery is a major cause of machine failure or malfunction, as a lack of balancing puts unnecessary stress on the bearings, shaft, and bearing supports.

Northeast-Western Energy Systems will perform field balancing anywhere you need us to - at your facility, on your vessel, or offshore location - on motors and generators that are deemed out of balance through vibration analysis trending.

Our factory trained and experienced field service technicians, paired with our state-of-the-art field balance equipment, can handle all of your field balancing needs - and minimize your downtime while allowing for operation immediately after the balance is complete.

Reducing vibration can reduce the stresses to equipment, chances of premature mechanical failure and extend the mechanical life of your rotating equipment. Some motors or generators are not candidates for field balancing due to sealed endbells or limited access to rotor end caps.

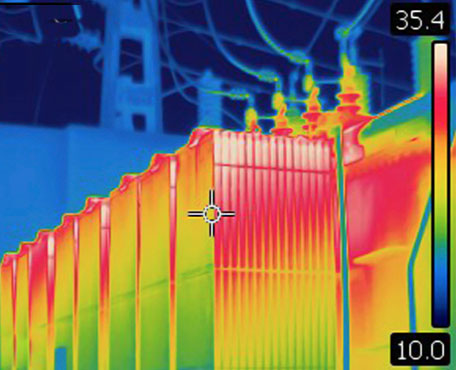

When you develop your maintenance program to avert costly failures on your offshore locations, vessels and facilities, it is critical that you include thermal imaging as a monitoring technique to extend the life of your electric motors, generators and electrical systems.

Thermal imaging is a non-invasive diagnostic method that is performed while your equipment is running under normal operating conditions.

Northeast-Wester Energy Systems experienced field service technicians utilize state-of-the-art thermal imaging technology to detect temperature rises on bearings as well as temperature rises on electrical connections to identify loose terminal or soldered connections. Once completed, we provide you with recommended repair scenarios to correct the issues.

Northeast-Western Energy Systems provides Planned Maintenance Agreements (PMA) testing that can help improve reliability, ensure the best return on asset value, decrease costly downtime and decrease catastrophic failures. The lifespan of a motor or generator can be optimized using the trending data and information obtained from a quality piece of test equipment and a highly trained technician. Northeast-Western Energy Systems can trend the condition of AC induction, synchronous, wound rotor, DC motors and their associated circuits.

We track and trend 6 major fault zones, all are monitored, measured and recorded for trending and analysis purposes:

Maximize the life of your STAMFORD® alternator by following the recommended scheduled service and repair activities in this easy-to-understand guide. Activities include:scheduled service and repair activities in this easy-to-understand guide. Activities include: Commission, Post Commission 250 hours/6 months, 1,000 hours/1 year service, 10,000 hours/2 year service and 30,000/5 year Service Kits for the following models: