long term service agreements

silver program

SILVER programs provide scheduled services and component replacement by NES-WES factory trained technicians. Owner personnel performs routine daily, weekly, and monthly inspections & services. The plan includes support via the NES-WES remote monitoring and troubleshooting center.

Customer provides operations and performs inspections-maintenance independent of the number of operating hours.

- NES-WES performs planned inspections, maintenance intervals, and component changes every 2000 OPH.

- NES-WES provides unplanned, corrective repairs at an additional charge on a T&M basis at discounted rates.

- NES-WES can supply oil and provide comprehensive oil management (oil testing, laboratory analysis, exchanges, disposal).

- NES-WES provides oil sample bottles for customer use as well as lab analysis and reports.

Options:

- NES-WES Lube oil, coolant sampling analysis

- Annual alignment

- Annual vibration test

- Annual infra-red scan

- 24/7/365 Asset Performance Management

- Quarterly equipment operating reports

gold program

GOLD programs provide comprehensive parts and service support. NES-WES Jenbacher factory trained technicians to perform scheduled services, and component replacement. With this program, our technicians will also perform unplanned, corrective repairs of the engine, generator, and Di.ANE control panel.

Customer provides operations and performs inspections-maintenance independent of the number of operating hours.

- NES-WES performs planned inspections, maintenance intervals, and component changes every 1000 OPH.

- NES-WES provides unplanned, corrective repairs.

- NES-WES can supply oil and provide comprehensive oil management (oil testing, laboratory analysis, exchanges, disposal).

- NES-WES provides oil sample bottles for customer use as well as lab analysis and reports.

Standard:

- NES-WES coolant sampling and fluid analysis

- Annual alignment

- Annual vibration test

- 24/7/365 Remote Monitoring

platinum program

platinum

NES-WES provides operations and performs:

- Inspections-maintenance is independent of the number of operating hours.

- Provide and maintain daily operating logs; daily, weekly, and monthly reports; assist the customer with operating permits, coordinate hazardous waste disposal, and coordinate emissions testing and reporting.

- Planned inspections, maintenance intervals, and component changes for Jenbacher equipment.

- Unplanned, corrective repairs on covered equipment.

- NES-WES can supply oil and provide comprehensive oil management (oil testing, laboratory analysis, exchanges, disposal).

- NES-WES lube oil and coolant sampling and fluid analysis.

- Annual alignment.

- Annual vibration test.

- Annual infra-red scan.

- 24/7/365 Remote Monitoring.

- Availability guarantees.

- Daily plant status and monthly equipment operating reports.

balance of plant

balance of plant

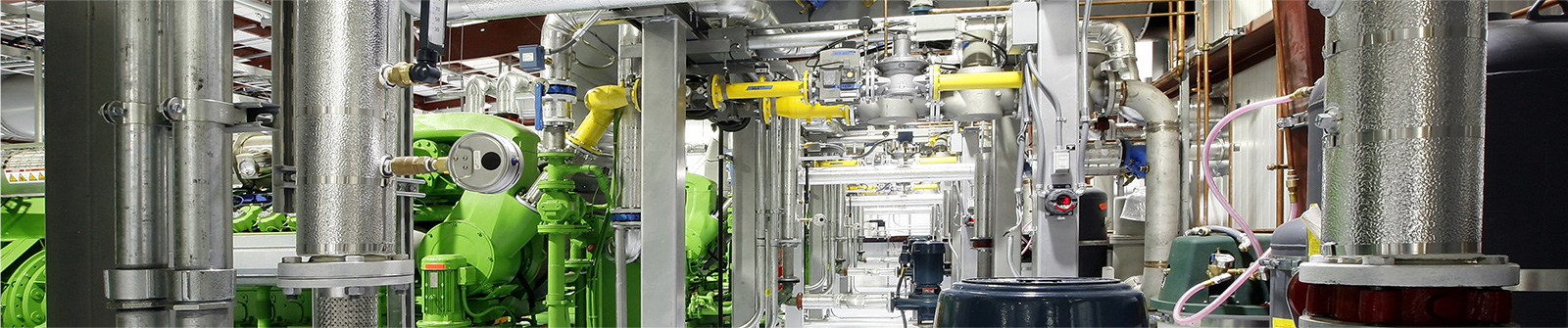

In addition to engine & alternator maintenance NES-WES can provide maintenance and overhauls for BOP items such as the following:

Options for Balance of Plant coverage

- Cooling systems, heat recovery, SCR.

- Infrared Scanning.

- Electrical maintenance audits.

- Electrical maintenance and testing.

- NES-WES performs planned inspections, maintenance and asset review every 1000 OPH.

- Quarterly equipment operating reports.

Examples of covered equipment

- SCR/Oxicat

- Exhaust Gas Heat Exchanger (EGHE)

- Container maintenance

- Radiators & Pumps

- Consumables

balance of plant

In addition to engine & alternator maintenance NES-WES can provide maintenance and overhauls for BOP items such as the following:

Options for Balance of Plant coverage

- Cooling systems, heat recovery, SCR.

- Infrared Scanning.

- Electrical maintenance audits.

- Electrical maintenance and testing.

- NES-WES performs planned inspections, maintenance and asset review every 1000 OPH.

- Quarterly equipment operating reports.

Examples of covered equipment

- SCR/Oxicat

- Exhaust Gas Heat Exchanger (EGHE)

- Container maintenance

- Radiators & Pumps

- Consumables